News Center:

Product display

Product displayProduct center

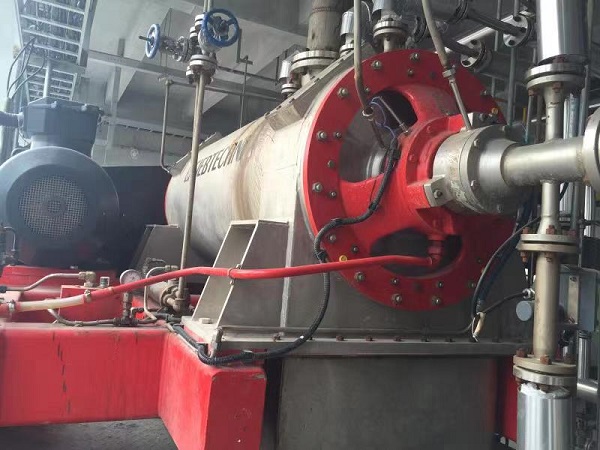

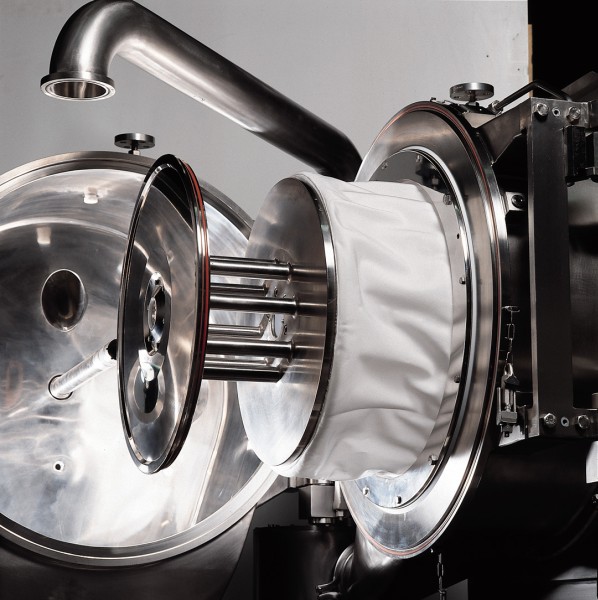

Product centerGermanyHeinkel

Heinkel drying and separation group of Germany has a history of 140 years and enjoys a high reputation in vacuum drying and stirring, filtration and centrifugation technology all over the world. Specializing in the design, manufacture and sales of high-quality solid-liquid separation equipment and systems. Centrifuges and dryers have special process equipment and general control system. The dryer is especially suitable for drying dangerous goods and toxic substances with solution or water. With the help of its closed design and indirect product heating method, the products with low water content are finally processed.

View details >>

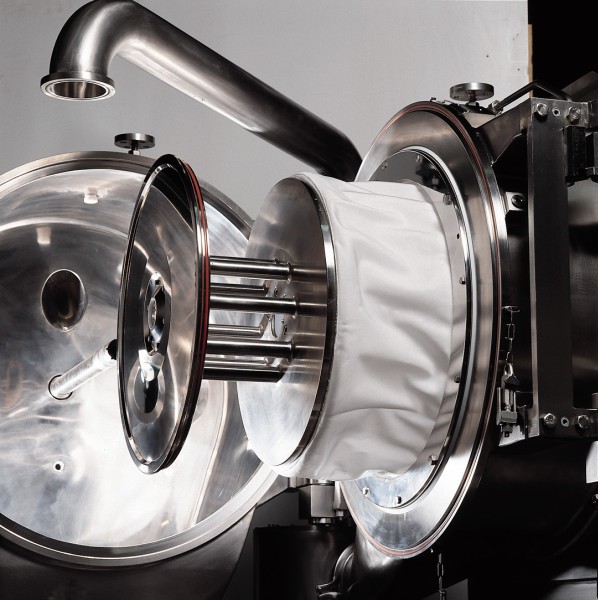

TM sieve Deli centrifuge

German sieve Deli is a leading manufacturer in the solid-liquid separation industry in the world, with nearly 100 years of technology accumulation. Tianma sieve Deli centrifuge is used for continuous solid-liquid mechanical separation. In almost all mechanical solid-liquid separation, continuous centrifuge is the most advanced and economical in technology. It can dehydrate a large number of solid materials, occupies a small area and saves energy and time. Spiral screen centrifuges, pusher centrifuges and double cone sedimentation centrifuges are equipped with ATEX explosion-proof system according to the standards of EU directives to meet the working requirements in dangerous areas.

View details >>

Sanitary centrifugal pump

Furan (Shanghai) Fluid Technology Co., Ltd. mainly produces sanitary centrifugal pumps, shear pumps, self-priming pumps, etc. All HPC series centrifugal pumps adopt open impeller design, which meets the most stringent requirements of sanitary and sterile working conditions. The special 316L stainless steel material and solid integral casting ensure the pressure resistance, earthquake resistance and anti-corrosion of the pump. A series of centrifugal pumps with soft delivery, high efficiency delivery, long service life and low maintenance cost are very suitable for pharmaceutical, daily chemical, food, beverage, fine chemical and other health fields.

View details >>

Dry vacuum pump

Dry vacuum pump is more and more widely used in the field of general unemployed. These vacuum pumps can be used as an integral unit of the process flow, and must meet a series of strict requirements. Their characteristics include: minimum working fluid treatment cost; Because lubricating oil and working fluid are not used, a completely clean vacuum can be provided; Mobility requirements applicable to batch operations; Very low life cycle cost. The dry vacuum pump has the advantages of simple structure, high efficiency, safety, reliability and durability. It can handle a variety of entrained liquid and solid particle media and changing operating conditions. The dry vacuum pump runs completely dry, and there is no lubricating oil or sealing fluid between the two screws. The suction capacity of a standard single pump ranges from 100 to 1000m3 / h, which can be combined with roots pump to achieve higher capacity.

View details >>

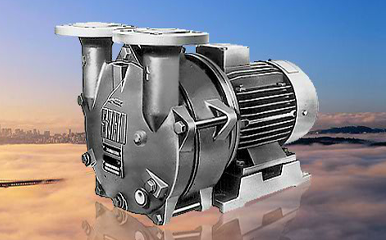

Germany SIHI

SIHI liquid ring vacuum pump is a positive displacement pump with simple structure and reliable use. Features: almost isothermal compression, no pollution; In the working chamber, the air does not need lubrication, so there is absolutely no oil It can handle almost all gas and steam, easy maintenance, high reliability, low noise and almost no vibration It can handle a small amount of entrained liquid and has a wide selection of materials. It can be used in all occasions. The shaft does not contact the medium, integrated sewage discharge and integrated central discharge. SIHI's full range of liquid ring vacuum pumps include single-stage and two-stage designs with inlet pressure between 33 and 1013mbar (a). If the inlet pressure is greater than atmospheric pressure, these pumps can be used as compressors. SIHI liquid ring vacuum pump / compressor and unit are suitable for various operating conditions, and have a wide range of materials and special materials, such as Hastelloy, titanium and duplex stainless steel. LEM / LEL series adopts pump coaxial design, which has the advantages of compact structure, lighter weight, lower noise, wide selection of materials and simple maintenance. It is mainly used in food processing industry (such as food processing factory, dairy farm), pharmaceutical industry, packaging industry and chemical industry.

View details >>