Products

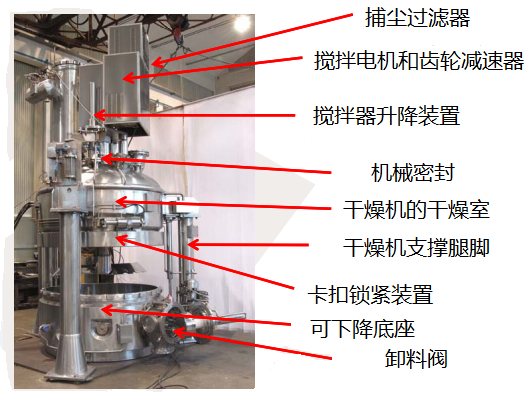

Three in one filter dryer

summary

The three in one filter dryer is a mechanical equipment integrating three production processes: material filtration and separation, material washing (sterilization) and material drying.

model:

PF 100 ~ PF 6000

Parameters:

Filtering area: 0.2 ~ 6.0 M2

Usable volume: 100 ~ 6000 L

Main features:

1. Comply with cGMP and FDA standards;

2. Multifunctional, suitable for different pharmaceutical production;

3. The structural design is reasonable, and the base can be extended down and opened;

4. The filter plate can be replaced, and the filter plate with corresponding aperture can be selected according to the diameter of material particles;

5. High drying efficiency, all surfaces in contact with materials have heating function;

6. It can realize on-line cleaning and sterilization without dead corner;

7. Optimized unloading system ensures complete unloading without residue.

The processes involved in the production of crystals of biomedical or chemical products are generally as follows:

Reaction process

Separation process

Washing process

Drying process

The equipment integrating any two processes is referred to as two in one equipment, the equipment integrating three processes is referred to as three in one equipment, and the equipment integrating four processes is referred to as four in one equipment.

Heinkel's equipment can be two in one, three in one and four in one functions, and can be adjusted according to the actual needs of customers.

Type selection information:

1. Solid liquid mixing ratio of materials

2. Viscosity of the material (so as to judge whether the material is suitable for drying by this kind of dryer);

3. Normal distribution of material crystal particle diameter (for optional filter plate);

4. The amount of materials to be dried every day (in order to calculate the amount of drying each time, and then the capacity of the dryer can be selected);

5. Physical properties of the material (if it is sensitive to temperature, the drying temperature needs to be controlled);

6. Chemical characteristics of dry materials and solvents (acid or alkali corrosivity, oxidizability, toxicity, etc.);

7. Recovery of solid phase materials or liquid phase materials

8. Dryer placement space and environment