Products

FP single stage centrifugal pump

Pumping performance

1. Minimum secondary eddy current

The open impeller is designed with a precise and narrow gap between the impeller and the end cover to form an optimized pumping channel to ensure that only the smallest secondary vortex is generated and the medium is treated gently under the condition of large flow

2. The medium viscosity can be as high as 1200mpas

The viscosity of the products delivered by the pump can be as high as 1200mpas. More importantly, the products delivered by our pumps can contain air or other gases, homogeneous or heterogeneous, and suspensions containing solid particles.

3. The value of NPSH is very low

The net positive inlet pressure (NPSH) of fristam FP pump can work normally even in adverse suction environment.

4. No pollution

The double mechanical seal ensures that the pump can work normally even under vacuum, protects the product from pollution and eliminates the possibility of environmental pollution caused by product leakage.

Quality of pump

Solid design, no danger operation (the pump is completely made of solid stainless steel with a wall thickness of no less than 6mm), durable mechanical seal and hygienic design

save

1. The best solution for you

Different design improvements can be made according to the nature of your products, processing technology and equipment characteristics.

2. Simple maintenance

Fristam FP pump is easy to disassemble and replace vulnerable parts in a period of time.

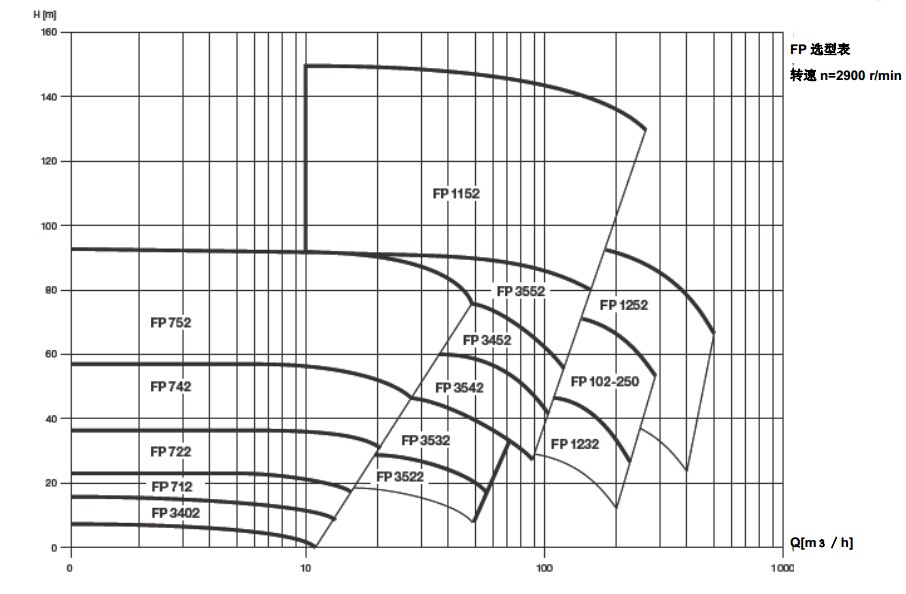

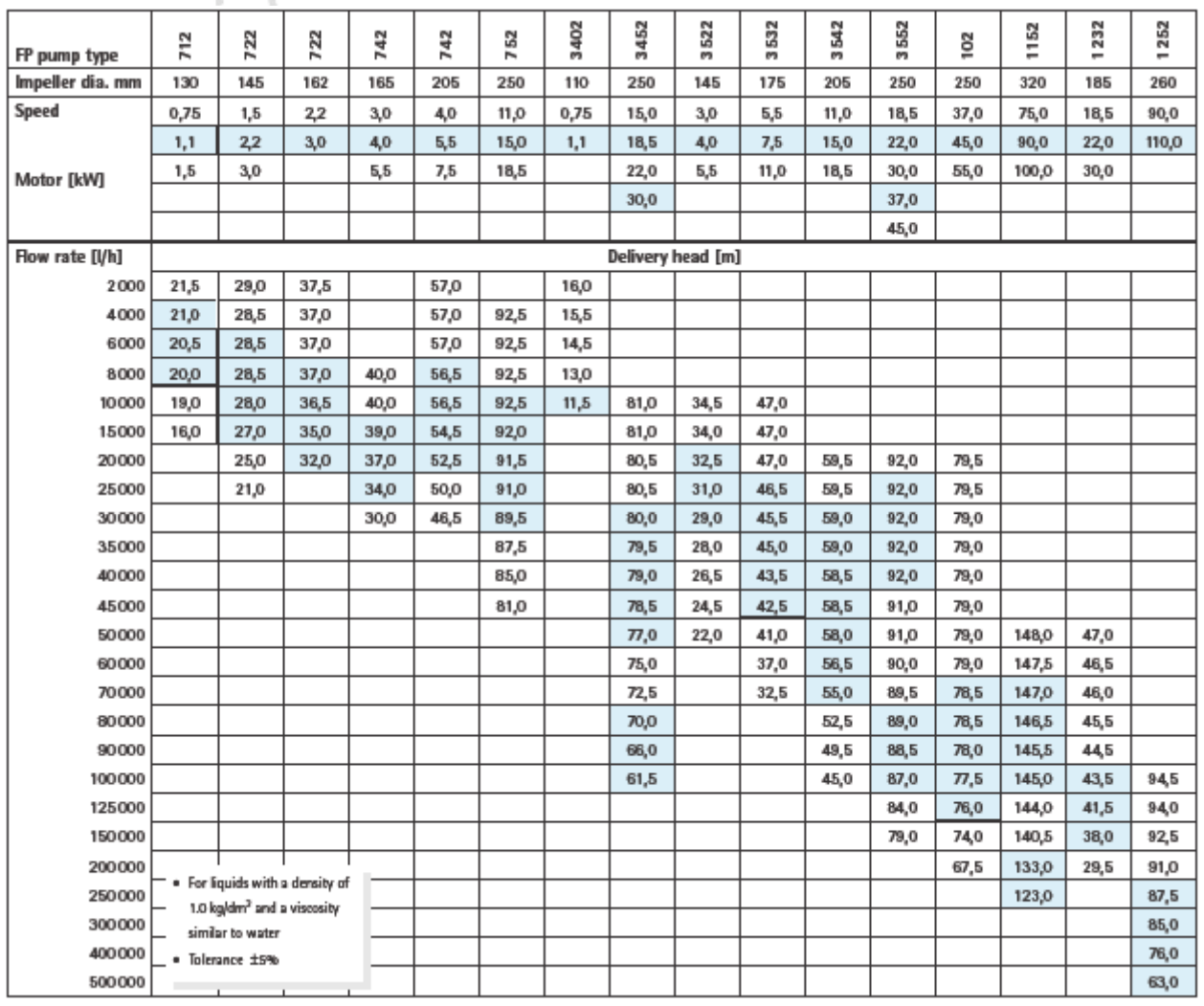

FP performance curve product application

1. Minimum secondary eddy current

The open impeller is designed with a precise and narrow gap between the impeller and the end cover to form an optimized pumping channel to ensure that only the smallest secondary vortex is generated and the medium is treated gently under the condition of large flow

2. The medium viscosity can be as high as 1200mpas

The viscosity of the products delivered by the pump can be as high as 1200mpas. More importantly, the products delivered by our pumps can contain air or other gases, homogeneous or heterogeneous, and suspensions containing solid particles.

3. The value of NPSH is very low

The net positive inlet pressure (NPSH) of fristam FP pump can work normally even in adverse suction environment.

4. No pollution

The double mechanical seal ensures that the pump can work normally even under vacuum, protects the product from pollution and eliminates the possibility of environmental pollution caused by product leakage.

Quality of pump

Solid design, no danger operation (the pump is completely made of solid stainless steel with a wall thickness of no less than 6mm), durable mechanical seal and hygienic design

save

1. The best solution for you

Different design improvements can be made according to the nature of your products, processing technology and equipment characteristics.

2. Simple maintenance

Fristam FP pump is easy to disassemble and replace vulnerable parts in a period of time.

FP performance curve product application

Selection table of FP single-stage centrifugal pump

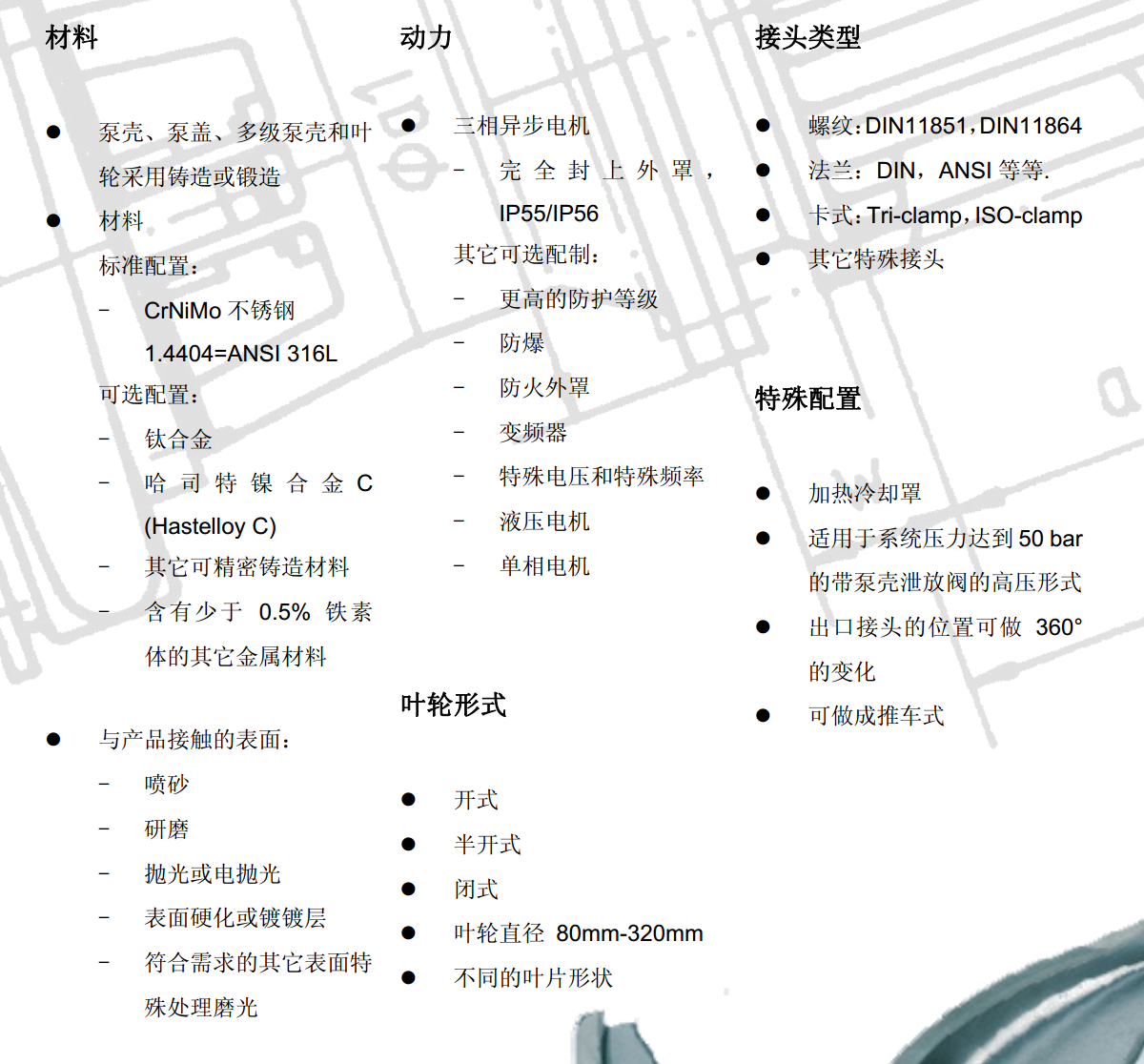

配置选项

Mechanical seal options

Product application

Dairy products, raw milk, whey, cheese, skimmed milk, concentrated

Milk, concentrated whey, coagulated milk

food

Animal and vegetable fats and oils, vinegar, soy sauce, sauce,

Seasoning, salt water, meat soup, tomato juice, vegetable

Vegetable water, juice, mayonnaise, whole egg

Sugar / candy

Syrup, molasses, starch solution

brew

Wort, yeast, beer, hot or cold wheat

Bud juice, low alcohol or non-alcoholic beer waste liquid,

CIP system

Alcoholic beverages

Liqueur, wine, champagne, distilled beer,

Spirits, alcoholic solutions

Non alcoholic beverages

Fruit juice, concentrated juice, syrup, mineral water, containing CO2

Mixed drink, concentrated puree

Chemicals

Photographic emulsion, acid-base solution, containing crystals

Wastewater, slightly polluted liquid, chemically polluted

Wastewater, cleaning fluid, adhesive

pharmacy

Pure water, injection, medicinal lotion, extraction of traditional Chinese Medicine

Liquid, perfume

bioindustry

Cell suspension, nutrient solution, enzyme, toxic solution,

Alcohol solution

papermaking

Glue, starch solution, resin solution, kaolin

solution

Application system and processing technology

Feed extraction during filtration, heating and filling

There is dry distillation in the ultrafiltration system, dealcoholization and separation of treated water

Transportation, circulation and pressurization heating in the process of hazardous substances and recovered product waste liquid

Feed fermentation of evaporation and superheat treatment system

Acceleration, pressure establishment, emulsification and homogenization in carbonization, mixing, metering and cleaning systems

The residue from cleaning the product pipeline is returned to the CIP system for on-line cleaning and dialysis

Emptying and feeding of containers and tanks

Sampling exhaust

Filling and emptying transfer of tank car

Water treatment cleaning system / CIP

Concentration on-line mixing

Distillation emptying

Dealcoholization sampling

reverse osmosis

filter

The best product needs the best pump

Fristam stainless steel pumps have customers all over the world, most of whom are in food, beverage, pharmaceutical and chemical industry

A large company with a leading position in the industry. Fristam pump is the best choice for pumping products for you

Dairy products, raw milk, whey, cheese, skimmed milk, concentrated

Milk, concentrated whey, coagulated milk

food

Animal and vegetable fats and oils, vinegar, soy sauce, sauce,

Seasoning, salt water, meat soup, tomato juice, vegetable

Vegetable water, juice, mayonnaise, whole egg

Sugar / candy

Syrup, molasses, starch solution

brew

Wort, yeast, beer, hot or cold wheat

Bud juice, low alcohol or non-alcoholic beer waste liquid,

CIP system

Alcoholic beverages

Liqueur, wine, champagne, distilled beer,

Spirits, alcoholic solutions

Non alcoholic beverages

Fruit juice, concentrated juice, syrup, mineral water, containing CO2

Mixed drink, concentrated puree

Chemicals

Photographic emulsion, acid-base solution, containing crystals

Wastewater, slightly polluted liquid, chemically polluted

Wastewater, cleaning fluid, adhesive

pharmacy

Pure water, injection, medicinal lotion, extraction of traditional Chinese Medicine

Liquid, perfume

bioindustry

Cell suspension, nutrient solution, enzyme, toxic solution,

Alcohol solution

papermaking

Glue, starch solution, resin solution, kaolin

solution

Application system and processing technology

Feed extraction during filtration, heating and filling

There is dry distillation in the ultrafiltration system, dealcoholization and separation of treated water

Transportation, circulation and pressurization heating in the process of hazardous substances and recovered product waste liquid

Feed fermentation of evaporation and superheat treatment system

Acceleration, pressure establishment, emulsification and homogenization in carbonization, mixing, metering and cleaning systems

The residue from cleaning the product pipeline is returned to the CIP system for on-line cleaning and dialysis

Emptying and feeding of containers and tanks

Sampling exhaust

Filling and emptying transfer of tank car

Water treatment cleaning system / CIP

Concentration on-line mixing

Distillation emptying

Dealcoholization sampling

reverse osmosis

filter

The best product needs the best pump

Fristam stainless steel pumps have customers all over the world, most of whom are in food, beverage, pharmaceutical and chemical industry

A large company with a leading position in the industry. Fristam pump is the best choice for pumping products for you