Products

Pre thickened spiral screen centrifugal

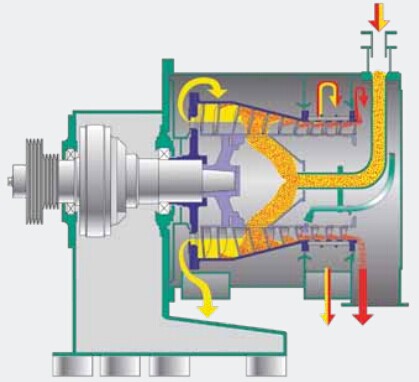

The centrifuge is developed and designed according to the sieve Deli conturbex spiral screen centrifuge. The slurry enters the sedimentation section of the centrifuge through the feed pipe and the distribution cone in the middle of the helix. The slurry with low solid content is pre dehydrated to achieve the thickening effect and effectively ensure the clarification of the sedimentation section. Most of the liquid is discharged through an adjustable overflow device on the back side of the centrifuge to separate the clarified liquid. The solid material is pre thickened and transported to the screen of the centrifuge for further dehydration, and flushing can be arranged if necessary. According to production needs, two streams of liquid can be discharged separately, or combined into one stream and discharged through a single cyclone or double hydrocyclone. The loss of fine particles is relatively low. If the liquid separated from the screen is returned to the feed, the loss of particles can be minimized. The solid material left on the screen basket is transported axially from the screen to the blanking area through the screw.

Typical application

N crystals, particles or fibers have good precipitation properties;

N in RRSB chart, particle size d '> = 0.050mm;

N the concentration of solid feed into the centrifuge is 0-60wt% (wt%: percentage by weight)

Main advantages

N long service life of screen basket components

N high output (small solid loss)

N high dryness of finished products

N cantilever design can meet:

N the screen is easy to replace without dismantling the screw;

N the design of the sealing device is simple.