Products

Vibrating centrifuge

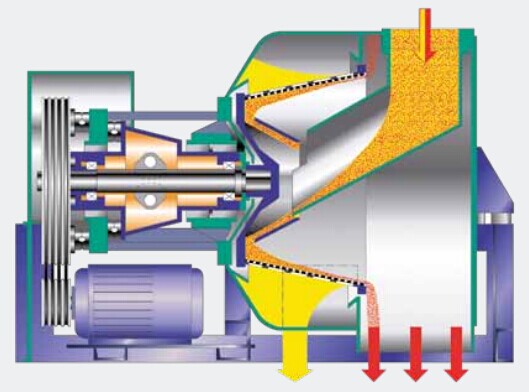

In terms of the output of solid materials, vibrating centrifuge is our most effective centrifuge. The conveying movement of solid particles in the sieve basket is carried out through the joint action of the inclination and axial vibration of the sieve basket. The premise of controlling the sliding speed is that the inclination angle of the screen basket is slightly smaller than the sliding friction angle of solid particles, and the acceleration of axial vibration is enough to overcome the remaining friction. Due to the limitation of the structure, the vibration acceleration is limited to a relatively narrow range, so it is normal

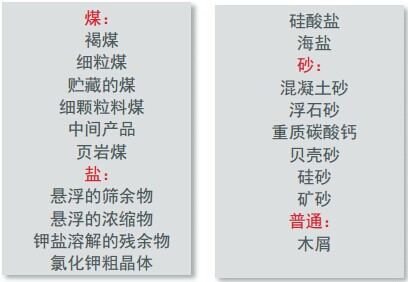

The vibrating centrifuge should work under the centrifugal force of 120g. Therefore, the machine is first used to process coarse particles or large quantities of products that are easy to dehydrate, such as fine coal washed in coal washing, intermediate products or fine stones, dissolution and washing sediments in potassium salt pretreatment, sea salt, concrete sand, etc.

structure

The screen basket, feed pipe, shaft and bearing seat form a small mass vibration system, which is connected with the shell through rubber spring. It is mainly composed of transverse members and product shield. In the resonance region slightly smaller than the natural vibration frequency, the excitation is generated by the symmetrically arranged eccentric hammer. The power consumed is very low for producing a very stable vibration. When the machine bears a high load, that is, the agglomeration of small and medium-sized products in the screen basket increases, and its own vibration value decreases and approaches the speed of the vibrator, in other words, it is closer to the resonance state. This automatically increases the amplitude and the conveying speed of solid particles in the sieve basket. Therefore, "the machine itself works independently" is self-adjusting to adapt to the fluctuation of feed in a large range. The screen basket and vibration exciter are driven by three-phase motor through V-belt. This makes it easier to match the speed with the operating conditions. The main motor, oil tank and oil pump (used for oil circuit lubrication of all bearings) are installed on the base. The base is also equipped with rubber buffer to isolate the vibration of the centrifuge. Like all our continuous operation centrifuges, vibrating centrifuges can even be installed on high floors without special foundation.

texture of material

The shaped steel wire of wedge screen is made of chromium steel. The feed and discharge pipes are made of wear-resistant and / or corrosion-resistant materials as required. The product room is made of carbon steel. If necessary, rubber lining and special wear-resistant protection can be provided in the solid discharge room.