Products

DZ / St Spiral Sedimentation Centrifugal

brief introduction

In the sedimentation centrifuge, the clarification of liquid is carried out in the column drum, and the dehydration of solid is carried out in the cone through filtration or extrusion between filter cakes. When the sedimentation rate of the feed liquid is high enough, even very fine particles can be well separated in the sedimentation centrifuge

The settling rate depends on the particle size, shape, density difference between solid and liquid phases, and the viscosity of the liquid.

When the flocculant is added into the slurry or heated, the sedimentation rate will be greatly increased. Of course, the geometric structure and operating parameters of the equipment will also have an impact.

Design

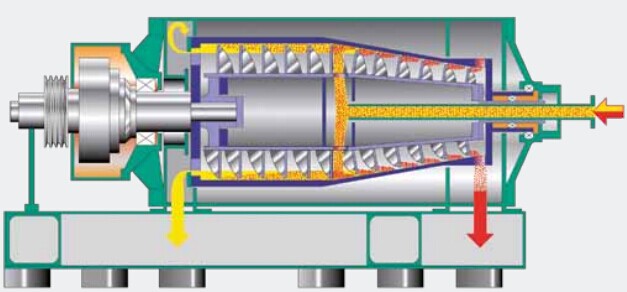

The German sieve force sedimentation centrifuge adopts the counter current working principle. That is, the suspension to be treated enters the centrifuge from the middle of the drum. The precipitated solid particles move to the small diameter end of the drum through the screw with differential speed with the drum, and the clarified liquid flows out reversely from the large diameter end of the drum.

The height of liquid level in the drum and the ratio of clarified liquid to solid particles can be adjusted, so that users can find the best separation effect. The differential between the screw and the drum is achieved by a powerful, shaped differential. The standard drive uses V-belt. According to the required speed combination, the centrifuge can be equipped with single drive (fixed eccentric shaft) or double drive (drive eccentric shaft).

1. ST series sedimentation centrifuge

TS series sedimentation centrifuges are mainly used in air tight process system. The closed product room, combined with the shaft seal design at the small diameter end and the adaptability of this design to the operating state, makes this series of centrifuges have high reliability.

In the sedimentation centrifuge, the clarification of liquid is carried out in the column drum, and the dehydration of solid is carried out in the cone through filtration or extrusion between filter cakes. When the sedimentation rate of the feed liquid is high enough, even very fine particles can be well separated in the sedimentation centrifuge

The settling rate depends on the particle size, shape, density difference between solid and liquid phases, and the viscosity of the liquid.

When the flocculant is added into the slurry or heated, the sedimentation rate will be greatly increased. Of course, the geometric structure and operating parameters of the equipment will also have an impact.

Design

The German sieve force sedimentation centrifuge adopts the counter current working principle. That is, the suspension to be treated enters the centrifuge from the middle of the drum. The precipitated solid particles move to the small diameter end of the drum through the screw with differential speed with the drum, and the clarified liquid flows out reversely from the large diameter end of the drum.

The height of liquid level in the drum and the ratio of clarified liquid to solid particles can be adjusted, so that users can find the best separation effect. The differential between the screw and the drum is achieved by a powerful, shaped differential. The standard drive uses V-belt. According to the required speed combination, the centrifuge can be equipped with single drive (fixed eccentric shaft) or double drive (drive eccentric shaft).

1. ST series sedimentation centrifuge

TS series sedimentation centrifuges are mainly used in air tight process system. The closed product room, combined with the shaft seal design at the small diameter end and the adaptability of this design to the operating state, makes this series of centrifuges have high reliability.

2. DZ series sedimentation centrifuge

DZ series sedimentation centrifuges are available in steam tight and air tight designs. In these applications, the product chamber consists of two parts sealed with packing rings. The geometry of the rotating parts is specially designed for special separation requirements. The fixing of rotating parts is realized by the support bearing outside the product room. In DZ series, the drum diameter of centrifuge is usually greater than 1000 mm.

Filtration sedimentation centrifuge is a combination of solid drum sedimentation centrifuge and spiral screen centrifuge. It has a particularly good effect on the dehydration of crystal and granular products. In the sedimentation section, the suspension is clarified first, and the pre dehydration is realized in the cone section of the solid drum. The pre dehydrated solid is transported to the cylindrical screen part through the screw for further dehydration. The special screen Deli cleaning system ensures the effective cleaning of the screen part of the centrifuge. Mother liquor and cleaning liquid can be discharged separately. Since the residual moisture of the material is less when passing through the screen part, the fine particles lost from the filtrate are also less, and the loss can be further reduced by returning this part of the filtrate to the centrifuge.

All sizes of sedimentation centrifuges listed in the sieve Deli product sample can be equipped with screen parts. The large-diameter filter sedimentation centrifuge can be equipped with a sheet screen, which can be directly replaced from the outside of the centrifuge to avoid the disassembly and movement of rotating parts. The advantages and equipment selection of all sieve Deli are applicable to this series.

Sieve Deli sedimentation centrifuge has a number of patented technologies and special designs, such as HD safety clutch to protect rotating parts to prevent overload under non sparking conditions. The design details at the liquid and solid outlets are shown in the figure. The liquid discharge outlet can be adjusted in a large range to meet the process requirements.

DZ series sedimentation centrifuges are available in steam tight and air tight designs. In these applications, the product chamber consists of two parts sealed with packing rings. The geometry of the rotating parts is specially designed for special separation requirements. The fixing of rotating parts is realized by the support bearing outside the product room. In DZ series, the drum diameter of centrifuge is usually greater than 1000 mm.

Filtration sedimentation centrifuge is a combination of solid drum sedimentation centrifuge and spiral screen centrifuge. It has a particularly good effect on the dehydration of crystal and granular products. In the sedimentation section, the suspension is clarified first, and the pre dehydration is realized in the cone section of the solid drum. The pre dehydrated solid is transported to the cylindrical screen part through the screw for further dehydration. The special screen Deli cleaning system ensures the effective cleaning of the screen part of the centrifuge. Mother liquor and cleaning liquid can be discharged separately. Since the residual moisture of the material is less when passing through the screen part, the fine particles lost from the filtrate are also less, and the loss can be further reduced by returning this part of the filtrate to the centrifuge.

All sizes of sedimentation centrifuges listed in the sieve Deli product sample can be equipped with screen parts. The large-diameter filter sedimentation centrifuge can be equipped with a sheet screen, which can be directly replaced from the outside of the centrifuge to avoid the disassembly and movement of rotating parts. The advantages and equipment selection of all sieve Deli are applicable to this series.

Sieve Deli sedimentation centrifuge has a number of patented technologies and special designs, such as HD safety clutch to protect rotating parts to prevent overload under non sparking conditions. The design details at the liquid and solid outlets are shown in the figure. The liquid discharge outlet can be adjusted in a large range to meet the process requirements.

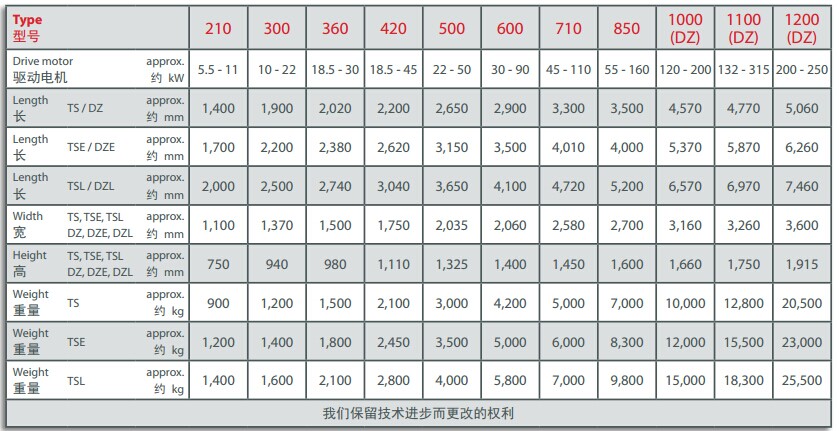

Standard technical parameters

Successful application cases