Products

Screen sedimentation centrifuge

brief introduction

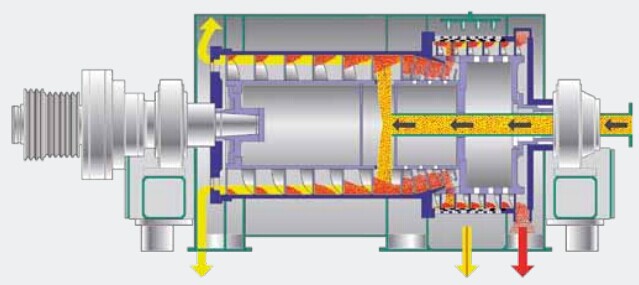

Screen sedimentation centrifuge is an equipment designed and developed by using advanced solid-liquid separation technology, which has obvious design and processing advantages. For the commonly used screen drum centrifuge, the screen part is connected to the minimum diameter of the cone section. The disadvantage of this design is that the capacity is limited, which increases the solid material layer and reduces the dehydration effect. Screen sedimentation centrifuge is a combination of the advantages of two-stage dewatering sedimentation centrifuge and filter centrifuge, so as to achieve the best effect.

In the first stage (settling section), the solid material is pre dehydrated in the cone section of the drum. The volume of the drum and the dryness of the cone section can be adjusted by using the overflow weir plate. The solid material after pre dehydration enters the next sieve basket with larger diameter from the cone section.

In the second stage (screen section), the filter cake is broken up and re formed. Due to the large capacity, the filter cake becomes thinner. At the same time, due to the large diameter of the screen basket, the centrifugal force on the filter cake is greater, which improves the dehydration efficiency and reduces the residual water. Since only a relatively small amount of liquid reaches the screen section with the solid material after pre dehydration, the loss of very fine particles passing through the screen is low and can be re transported to the centrifuge through recycling. Large diameter sieve basket and thin cake layer are also suitable for flushing. The flushing liquid can be discharged separately from the mother liquid.

Screen sedimentation centrifuge is an equipment designed and developed by using advanced solid-liquid separation technology, which has obvious design and processing advantages. For the commonly used screen drum centrifuge, the screen part is connected to the minimum diameter of the cone section. The disadvantage of this design is that the capacity is limited, which increases the solid material layer and reduces the dehydration effect. Screen sedimentation centrifuge is a combination of the advantages of two-stage dewatering sedimentation centrifuge and filter centrifuge, so as to achieve the best effect.

In the first stage (settling section), the solid material is pre dehydrated in the cone section of the drum. The volume of the drum and the dryness of the cone section can be adjusted by using the overflow weir plate. The solid material after pre dehydration enters the next sieve basket with larger diameter from the cone section.

In the second stage (screen section), the filter cake is broken up and re formed. Due to the large capacity, the filter cake becomes thinner. At the same time, due to the large diameter of the screen basket, the centrifugal force on the filter cake is greater, which improves the dehydration efficiency and reduces the residual water. Since only a relatively small amount of liquid reaches the screen section with the solid material after pre dehydration, the loss of very fine particles passing through the screen is low and can be re transported to the centrifuge through recycling. Large diameter sieve basket and thin cake layer are also suitable for flushing. The flushing liquid can be discharged separately from the mother liquid.

advantage:

N clarification and drying are carried out in two stages respectively;

N there is no interference between the clarification zone and the drying zone;

N when the solid material enters the screen section from the settlement section after pre dehydration, the filter cake is broken up;

N even if the output of solid materials is high, the large-diameter sieve basket can ensure sufficient capacity and relatively thin solid material layer;

N compared with the sedimentation section, the centrifugal force of the screen section is greater, so it can effectively remove the residual water in the filter cake after pre dehydration;

N high yield, less solid loss and recyclable filtrate;

N screen basket can be equipped with effective flushing;

N washing solution and mother liquor can be discharged separately.

Standard technical parameters

N clarification and drying are carried out in two stages respectively;

N there is no interference between the clarification zone and the drying zone;

N when the solid material enters the screen section from the settlement section after pre dehydration, the filter cake is broken up;

N even if the output of solid materials is high, the large-diameter sieve basket can ensure sufficient capacity and relatively thin solid material layer;

N compared with the sedimentation section, the centrifugal force of the screen section is greater, so it can effectively remove the residual water in the filter cake after pre dehydration;

N high yield, less solid loss and recyclable filtrate;

N screen basket can be equipped with effective flushing;

N washing solution and mother liquor can be discharged separately.

Standard technical parameters

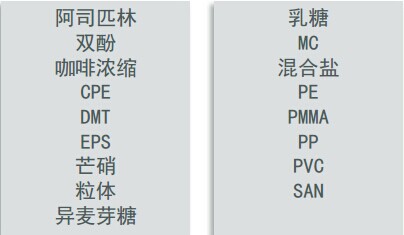

Successful application cases