Products

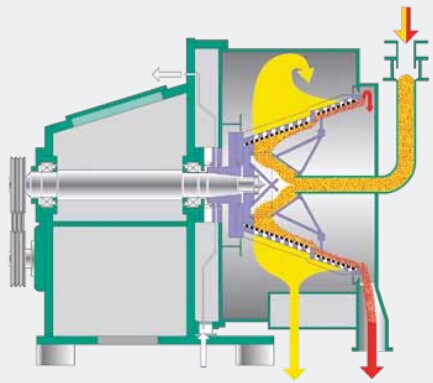

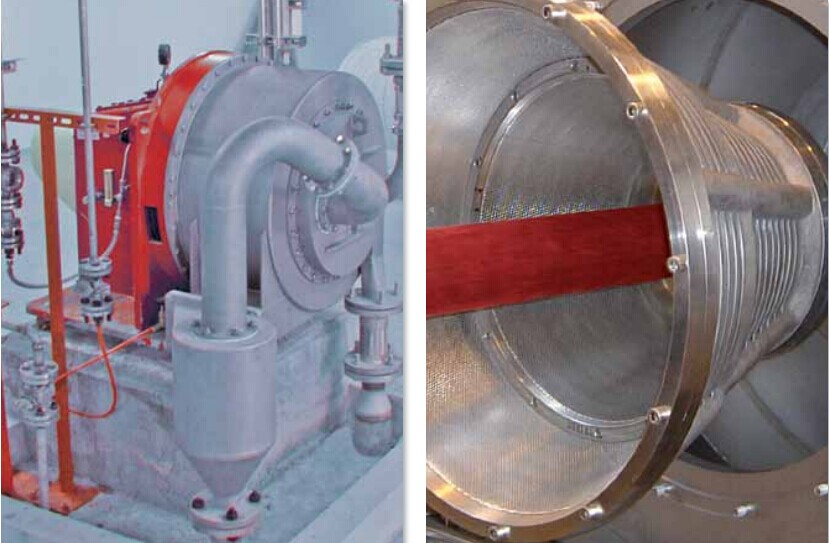

Step sliding discharge centrifuge

The sliding discharge centrifuge mainly aims at the dehydration of uniform solid particles more than 0.2mm. The particles slide individually on the screen without forming a dense layer. In order to dehydrate, it can be subdivided into several stages. The guide plate rotating with the screen basket directly sieves the mixture of air and solid particles and prevents particles from jumping over the screen area. Solid particles are only affected by centrifugal force for a short time. According to the nature of the product, the surface humidity can be reduced to less than 1%.

Choose to use perforated plate or conical screen according to the requirements and operating conditions. Due to the special guidance of the product, it will not be blocked by sharp particles.

Generally, the sliding discharge centrifuge is airtight / vapor tight, and the gas is recycled to the gas bin, and the circulating gas is separated from the water in the cyclone. The dehydrated solid particles are discharged along the tangent direction through a discharge pipe that can rotate to any direction. According to the needs of customers, corresponding machines can be provided for pre dehydration and removal of coarse particles or caking.

In order to avoid the influence of low feed concentration on the centrifuge, sieve Deli can provide Thickener (or static dehydrator).

成功应用案例